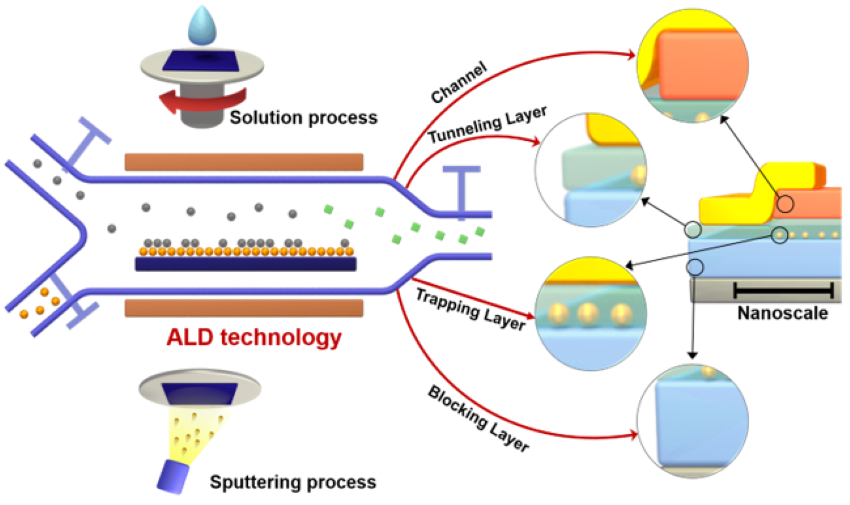

The concept of Atomic layer deposition (ALD) or Molecular layer deposition (MLD) was first proposed by Valentin Borisovich Aleskovskii of the Russian Academy of Sciences, and the first ALD device was invented by Dr. Tuomo Suntola of Finland in 1974. ALD is a thin film preparation process that can deposit substances layer by layer in the form of a single atomic layer. The process is to form the deposition film by alternately passing the pulse of the vapor phase precursor into the reactor and causing its chemisorption and reaction on the deposition substrate. When the precursors reach the surface of the deposited substrate, they will chemically adsorb and react on the surface. The atomic layer deposition reactor is cleaned with an inert gas between the precursor pulses to remove excess precursor and reaction by-products. Therefore, the ALD process has the characteristics of self-limited growth, can accurately control the size of the film, the film has a uniform thickness and excellent consistency, and also particularly suitable for the large scale integrated circuit submicron deep groove structure of the film growth. The research directions of the research group in this field include new ALD reaction and growth process, ALD high-k film, ALD application in large scale integrated circuit copper interconnect barrier layer, ALD application of metal nanocrystals in Flash memory, and development of new organic or organic/inorganic hybrid film by ALD/MLD process.

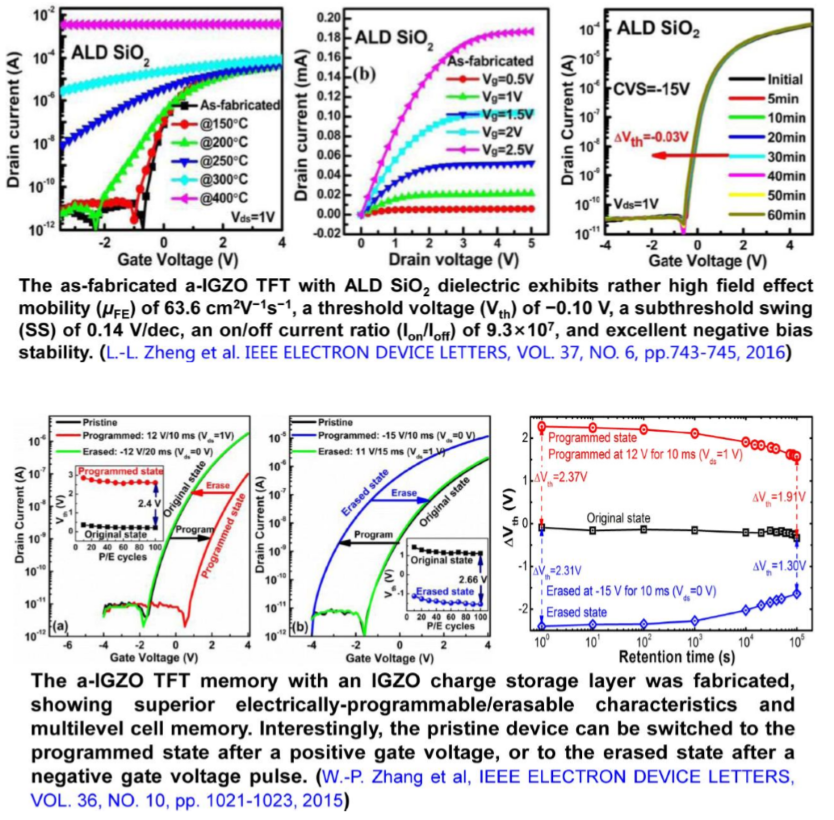

Wide bandgap oxide semiconductor ZnO, Ga2O3, In2O3, InGaZnO, and other multi-component systems have good application prospects in the fields of flat panel display, flexible electronics, transparent electronics, and power devices due to their large bandgap, visible light transparency, low preparation temperature, and high electron mobility. In recent years, with the rapid development of system-on-panel (SOP) technology, people need to integrate various components (such as switching components, digital interface drivers, non-volatile memory, dynamic memory, contact sensors, solar cells, etc.) on the same display panel to obtain a high-performance, low-cost, low-power system and has an important application prospect in the fields of automobile, computer, consumer electronics, military electronics, wireless communication and food inspection. However, the thin-film transistor (TFT) as a switching device and the non-volatile memory as a data storage are the core components to implement SOP, so it is of great practical significance to study them. This research group mainly focuses on amorphous oxide semiconductor TFT, and researches low-temperature preparation of high-performance TFT devices to meet the performance and technological requirements of flexible electronics. For non-volatile memory, the research on charge trap memory based on oxide semiconductor TFT structure is carried out to explore the solution of increasing the electric erasing efficiency and realizing multi-stage storage, to solve the key problems restricting the overall performance improvement and high-density storage of the memory.

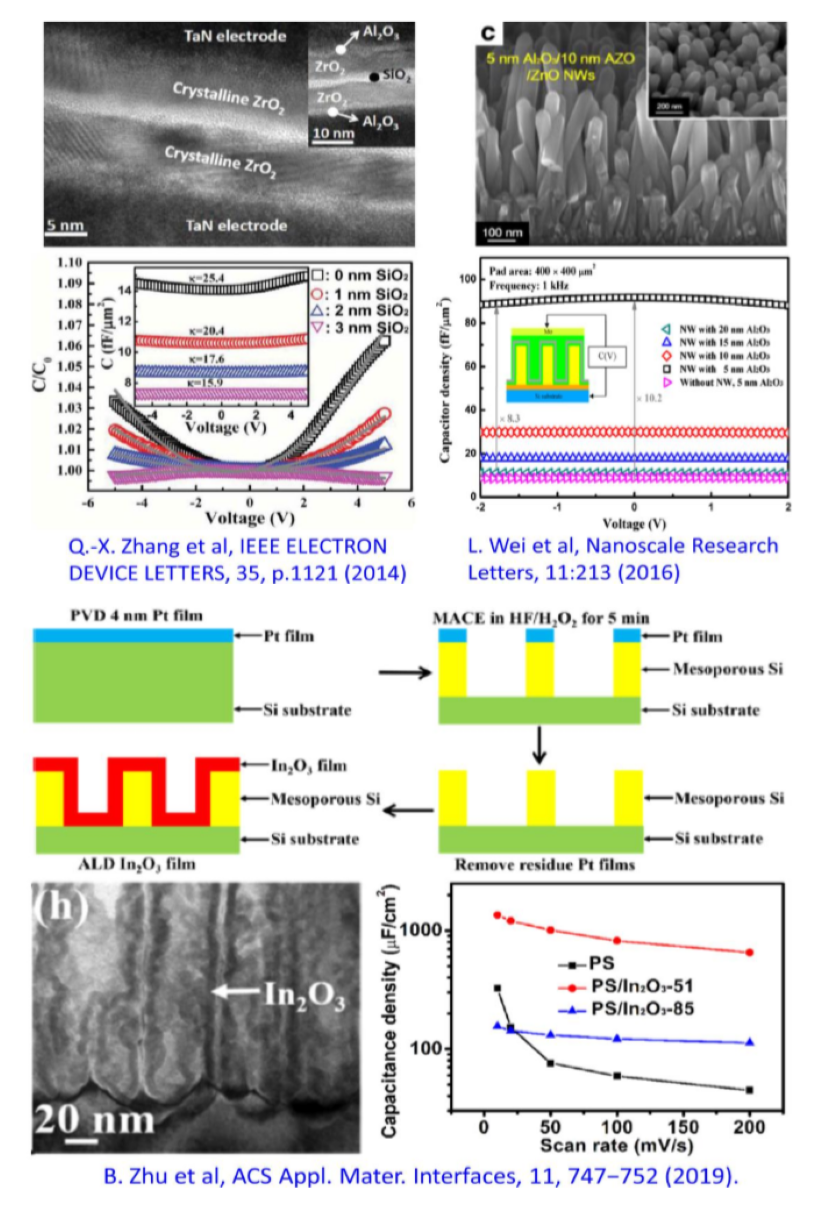

With the rapid development of wireless communication technology, high performance decoupling, and filtering capacitors need to be implanted into the copper interconnect terminal process of integrated circuits to obtain powerful RF systems. At the same time, the implanted capacitor must have high capacitance density, low leakage current density, ideal voltage linearity, accurate capacitance value control, low-temperature coefficient, and high reliability. Therefore, metal/insulator/metal (MIM) capacitance based on a metal electrode and the high dielectric constant medium has become the inevitable choice for the development of RF, analog/mixed-signal integrated circuits. How to improve the capacitance density is one of the key factors for the success of future wireless communication technology innovation. This research group focuses on the material selection and capacitor structure design of high-density MIM capacitors focuses on the process development of nanostructured MIM capacitors, solves the problems of materials, processes, and structures that restrict high-performance MIM capacitors, and deeply understands their potential mechanism of action.

With the rapid development of wireless power sensor networks and the Internet of things, the demand for high-performance on-chip energy storage devices is increasing, especially those that can be integrated into various kinds of silicon-based electronic devices. Compared with lithium-ion batteries, supercapacitors have attracted much attention due to their higher power density and longer cycle life. However, the low energy density of ultracapacitors has always been the main bottleneck restricting their practical application. Since pseudocapacitor has a higher energy density than an electric double-layer capacitor, our research group focused on the all-solid superpseudocapacitor on the chip, including the design and processing of nano-structure, the selection and preparation of electrode materials, and the development of solid electrolyte materials.